Here is more than you ever wanted to know about fixing my tankless water heater.

A few years ago I bought and installed a Poloma model RMTG-53DVP tankless water heater in my home. This exact same model is also sold under the brand names of Rheem, Ruud and Richmond. After operating for about a year it shutdown and started flashing error codes C7, 13 on the remote control. If I unplugged it for a while it would work again but would only run for about 3 minutes before shutting down again. Some digging around on the WEB indicated this was a oxygen sensor fault. In other words the oxygen sensor was telling the controller there was low oxygen. Never having worked on a tankless water heater before I called a plumber that advertized fixing tankless water heaters. He came out and we had a nice conversation and basically recommended I fix it myself. For this I paid for a service call. Apparently he was not familiar with that brand of heater and did not want to figure it out.

Now a tankless is way more complicated than a conventional water heater with a microcontroller and lots of sensors and valves.

Here is my heater opened up. At the top is the copper coil assembly where the water gets heated. The plastic with the black lines on that is an electric heater that keeps the water from freezing if the temperature gets too low. Below that is where the burner assembly goes. The burner assembly and manifold is removed in this picture. Below the burner assembly is the controller, valve and fan. There is a whole bunch of screws that have to be removed to get thing apart.

The oxygen sensor work by monitoring a flame burning in a special chamber. There is a precision orifice that controls the amount of gas burning and a thermocouple to monitor the flame temperature. The controller waits for 3 minutes after the heater starts to check the flame temperature so that everything is stabilized. If the temperature is too low the controller shuts down the heater and sends an error code to the remote control.

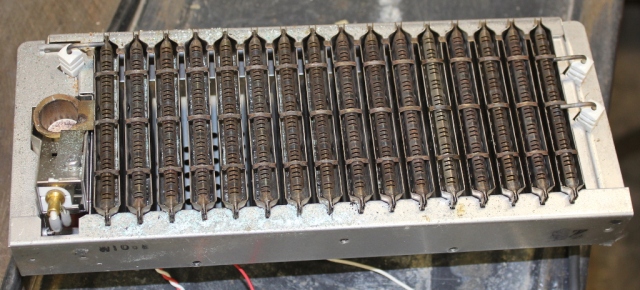

This is the burner assembly. On the left is a round brass hole. That is where the sensor flame burns.

So what could cause the problem? Obviously there is plenty of oxygen and nothing blocking the air flow into the heater. The thermocouple could be bad but those thing are very reliable. The controller board could be bad (horrors). After a bit of poking around and inspection I discovered that there was some crud deposits around the precision orifice.

It did not seem like the orifice was blocked that much but since I could not find any other problems I cleaned the orifice and reassembled the heater. That solved the problem.

Since then I have had to clean the orifice about once a year. Something in the propane is forming the crud. They also recommend cleaning the water lines by running vinegar through the heater with a pump for about an hour. I have done that once. It did not seem like there was very much lime build up though.

very helpful, got mine to work.

do you have the part # for the ODS Rheem will not give it to me they want me to spend 300.00 on whole new assembly can you help me with this

Sorry no part number.

The ODS itself is a rugged device and not real likely to fail. Did you try cleaning the orifice like I did?

I am having same exact problem, but with 2 kids under 1 and 12deg outside. Do you have any other pictures of disassembly?

Sorry, I only have the two that are in the article. You have to loosen the electronics assembly and remove the cover over the burner assembly. A lot of small screws to take out. Just be careful with the O ring seals for the gas when you put it back together. Make sure the rings are in place and there are now wires caught between the parts.

I took it apart last night and found the same picture. I wasnt going to do a full blown tear down till the weekend. I had lots of build up on the top of my burner. I didnt unhook any wirea going to the burner so I didnt see how to pull that little assembly out with brass piece. I believe its called the ODS sensor. Im not exactly sure if your saying the brass sensor is where that orifice is located or not? Im trying to have best game plan to save myself time tonight. thanks

If I remember correctly the orifice is in the cover that you took off to expose the burner assembly. The ODS (Oxygen Depletion Sensor) is a thermocouple (temperature sensor) that measures the temperature of a small flame burning in the round cup seen in the left of my picture of the burner assembly. If the temperature of the flame drops too low a fault is set. The orifice regulates the amount of gas to the flame.

Ok, i didnt pay much attention to the cover. I just took it off and set it down. Richmond(Rheem) doesnt provide crap for information on this issue.

I am having the exact same problem…I have checked the ODS and it looks good. Exactly where is the precision orifice? I can’t seem to find anything that looks like that (my model is a bit different). Thanks.

On my heater you have to remove about 20 screws that hold the gas manifold to the burner assembly to get access to the orifice.

Sorry for all these questions but I would love to get this heater working. On your picture above, have you already removed the gas manifold? I don’t see any screws on that burner assembly. Where is the precision orifice relative to the sensor’s flame brass hole? I am not 100% I am using the term correctly but my burner has two fuel rails one on each side of the burner assembly. Could it be I don’t have a precision orifice?

In the top picture, the aluminum colored rectangular area with the screw holes around the outside is where the burner assembly goes. On top of the burner assembly goes the manifold not shown in any picture which screws on with screws going into all the holes around the rectangular area. The orifice is in the inside of the manifold and sends the gas into the brass cup to be burned. I would think that if you have an ODS there has to be a orifice supplying the gas to be burned for the sensor. For sure you are not going to see the orifice without taking something apart.

Thanks so much for your reply. There is a small brass ring (not a small orifice like in your picture) where one of the gas tubes (my burner has three it looks like your has two) connects to the burner assembly and then flows into the ODS. I’ll double check that is clean but right now it is reassembled so we can use it but have to reset it after 3 minutes.